Doane Nets

How to make mosquito netting from recycled plastic bags

This page covers the basic techniques and ideas needed to make mosquito netting from recycled shopping bags.

Not going to Africa? You can still help! Spread the word! Send the link. Forward the e-mail. All that is lacking is knowledge on the ground. How many people can you contact in the affected areas? I can not stress this enough. All that is needed now is to spread the word.

If you are doing this on the ground, send me your stories and pictures! We will post them here!

We have developed three methods for making mosquito netting.

Cutting the holes with heat:

A video of this method can be found here.

Here is the tools video. It covers some of the failed tools we have used and a bit more on the heated cutting tool.

- Pros: If the cutting tool is good and your hand steady, an individual can easily get three holes for every one piece of plastic. If wood or coal is available then the equipment needed is very low tech and is easy to manufacture.

- Cons: For families that cook using a coal or wood fire, this method will be extremely expensive in terms of fuel.

After talking to Kenyan conservationist Isaac Kinyanjui, it became clear that the expense of heating the cutting tool would put the price of the mosquito netting well outside the means of most families living in malaria ridden areas.

Knowing that treadle sewing machines exist in many villages throughout Africa, he urged me to develop a way

to make the mosquito netting with a sewing machine. A typical sewing machine needle will not work. This is because, while the needle makes a hole, the hole quickly closes after the needle is removed (this is the reason we ruled out sewing machines early on in the development of the mosquito netting). So we set out to make the sewing machine work.

We were faced with having to design a needle tip that would not just punch a hole in the plastic but actually punch the chad free of the plastic. (A chad is the plastic hole punched out of the base material.) Hanging chads will make one side of the net fuzzy and dramatically increase wind resistance. After cutting many different tips, we found that a four-point tip worked the best. Cut correctly, the tip is successful about 95% of the time at punching the chad out cleanly. With just a little handling of the material an additional 2% of the hanging chads will fall free.

Cutting the holes with a sewing machine:

Below is the outline of how to make the mosquito netting using the base material, a sewing machine, and the four-pronged African needle.

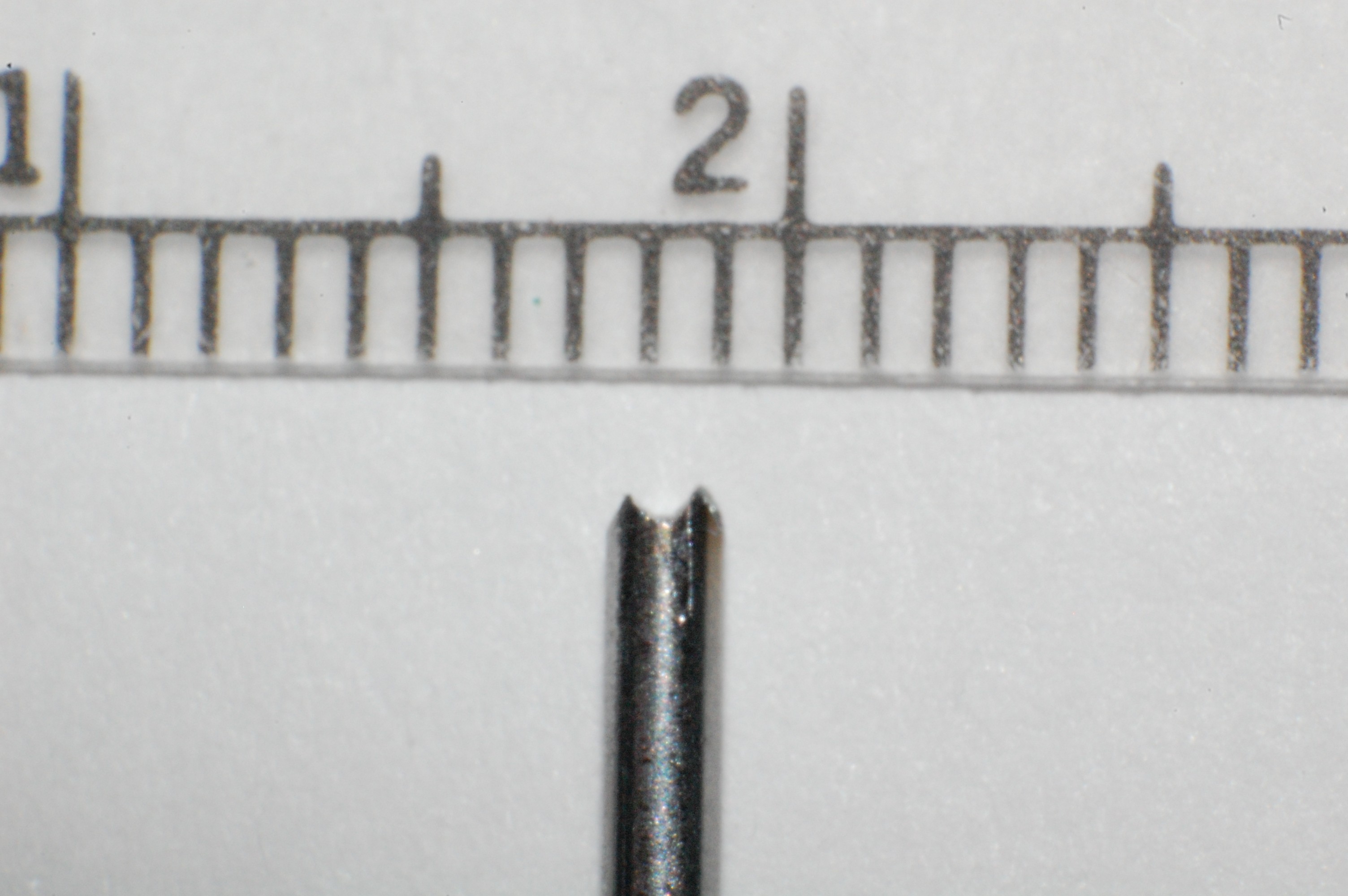

Cutting the needle:

To cut the needles you will need a nail that is 2mm or less in diameter.

Cut off the tip and the head.

Using a triangle file of any size (but the smaller the better) cut into the tip deep enough so that there is no longer a flat portion left to the point of the needle.

The cross cut seems to be the most critical step. Take time to center the cross cut and make it perpendicular to the first cut. Being off to either side and/or not being perpendicular seems to diminish the successfulness of the tip. The triangle cut creates a 60o angle regardless of the size of the triangle. Tips made this way are effective at removing chads about 90-95% of the time. The drawback of the triangle file is that it is not as common as a flat file with square sides. Cutting with the corner of these square files creates a 90o angle and is only effective about 50-60% of the time at removing the chads. They will punch holes and work nicely. In cool or cold climates squared-cornered files may be all that is required.

You now have an African needle.

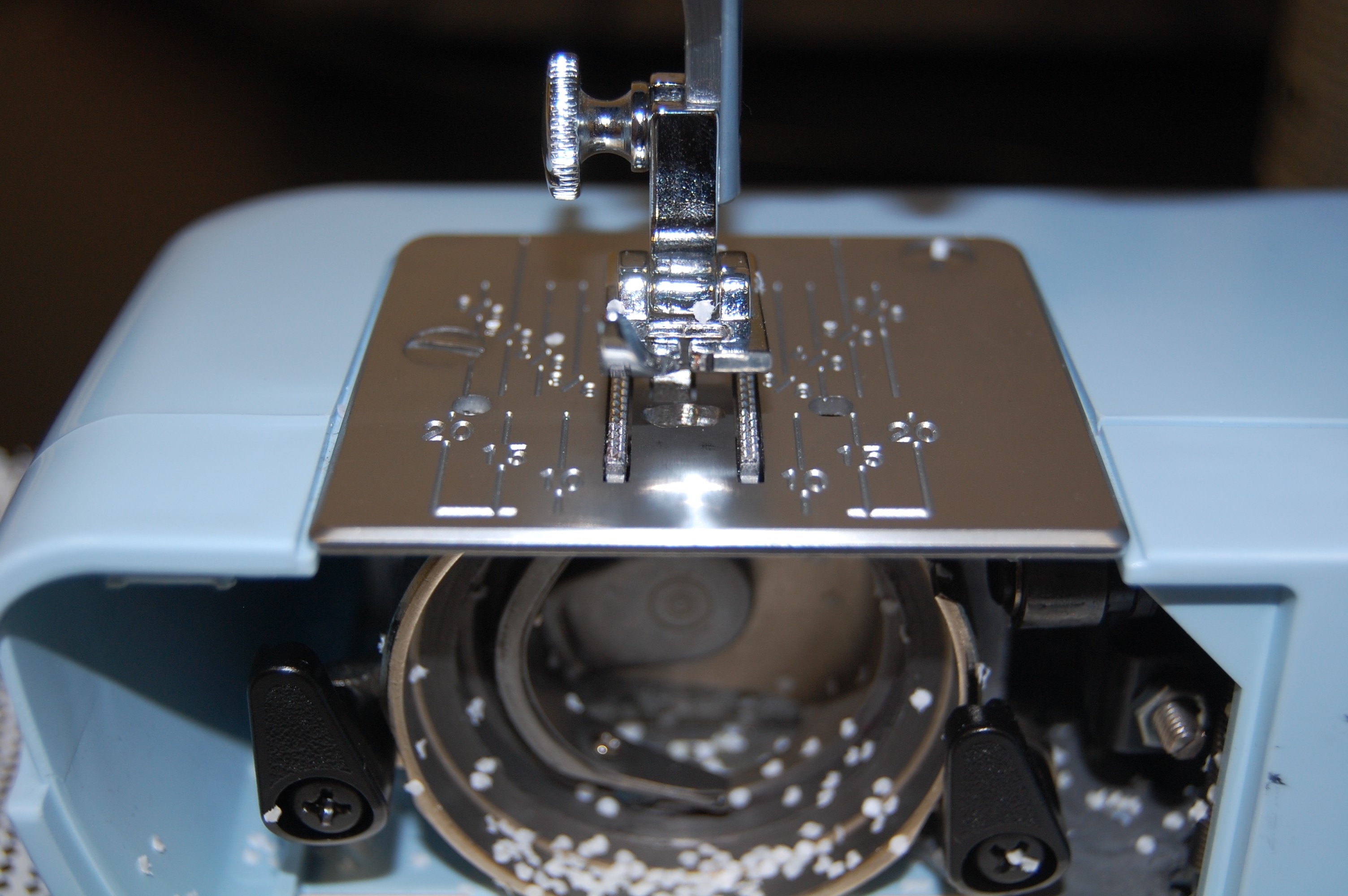

Prepping the sewing machine:

- First, You will have to remove the bobbin components below the deck of the sewing machine. The African needle is much thicker than a traditional needle and will jam/smash the bobbin mechanism. I was able to remove the mechanism without having to do any damage to the sewing machine.

- Second, you will probably need to widen the hole the needle passes through in the deck itself. Run your sewing machine slowly the first few strokes to make sure the needle clears.

Note the chads. Other projects I have been working on include melting this material further and making other products such as irrigation pipes, chalkboards (inspired by Karla Cooper), lumber, etc. So the chads are valuable and need to be recollected. It is a good idea to make a catch bag to collect the chads.

A view through the mosquito netting. Here four panels have been welded together.

Two points on punching out the chads: The distance between the stitches is adjustable with most sewing machines; the closer one can get the stitches the more airflow the net will have. Second, the closer together the rows of stitches can be placed the more airflow the net will have.

Cutting the holes using the finger needle:

If you don't have a sewing machine, you can still use the African needle as a finger needle. Making a finger needle is easy. Just leave the head of the nail in place. Cut the bottom like normal. This works great but takes more time. Keep in mind that in many situations, the air flow is not critical. Evening temperatures in the 40oF (4oC) can be common. In these situations, fewer holes might be desirable.

This technology also allows one to patch existing nets or add reinforcements to weak spots.

One can also use parts of pre-manufactured nets to create airflow windows and just use the plastic base material to provide full body cover.